TWS Flanged static balancing valve

Kev piav qhia:

TWS Flanged Static balancing valve yog ib yam khoom siv hydraulic balance tseem ceeb uas siv rau kev tswj cov dej ntws hauv HVAC daim ntawv thov kom ntseeg tau tias muaj kev sib npaug hydraulic thoob plaws tag nrho cov dej system. Cov koob no tuaj yeem ua kom muaj kev ntws tiag tiag ntawm txhua lub khoom siv kawg thiab cov kav dej raws li kev tsim qauv hauv theem ntawm kev pib ua haujlwm los ntawm kev ua haujlwm ntawm qhov chaw nrog lub khoos phis tawj ntsuas kev ntws. Cov koob no siv dav hauv cov kav dej tseem ceeb, cov kav dej ceg thiab cov kav dej khoom siv kawg hauv HVAC dej system. Nws kuj tseem siv tau rau lwm daim ntawv thov nrog tib yam kev ua haujlwm.

Cov yam ntxwv

Kev tsim thiab kev xam cov yeeb nkab yooj yim

Kev teeb tsa sai thiab yooj yim

Yooj yim ntsuas thiab tswj cov dej ntws hauv qhov chaw los ntawm lub khoos phis tawj ntsuas

Yooj yim ntsuas qhov sib txawv ntawm qhov chaw

Kev sib npaug los ntawm kev txwv stroke nrog digital presetting thiab pom presetting zaub

Nruab nrog ob lub cocks ntsuas siab rau kev ntsuas qhov sib txawv. Lub log tes tsis nce siab rau kev ua haujlwm yooj yim.

Kev txwv txoj hlab ntsha tawg-ntsia hlau tiv thaiv los ntawm lub hau tiv thaiv.

Lub valve ua los ntawm stainless hlau SS416

Lub cev hlau cam khwb cia nrog cov xim tiv taus corrosion ntawm epoxy hmoov

Cov ntawv thov:

HVAC dej system

Kev teeb tsa

1. Nyeem cov lus qhia no kom zoo zoo. Yog ua tsis tau raws li lawv yuav ua rau cov khoom puas tsuaj lossis ua rau muaj kev phom sij.

2. Saib cov qib uas tau muab rau hauv cov lus qhia thiab ntawm cov khoom kom paub tseeb tias cov khoom no haum rau koj daim ntawv thov.

3. Tus neeg teeb tsa yuav tsum yog tus neeg ua haujlwm tau kawm tiav thiab muaj kev paub dhau los.

4. Ib txwm ua qhov kev kuaj xyuas kom meej thaum kev teeb tsa tiav lawm.

5. Yog xav kom cov khoom siv tau yooj yim, kev teeb tsa zoo yuav tsum suav nrog kev ntxuav lub kaw lus thawj zaug, kev kho dej tshuaj thiab siv lub lim dej sab nraud 50 micron (lossis zoo dua). Tshem tawm tag nrho cov lim dej ua ntej ntxuav. 6. Xav kom siv cov yeeb nkab sim ua ntej ntxuav lub kaw lus thawj zaug. Tom qab ntawd txuas lub valve rau hauv cov kav dej.

6. Tsis txhob siv cov tshuaj ntxiv rau hauv boiler, cov kua nplaum thiab cov khoom siv ntub dej uas yog roj av lossis muaj roj av, hydrocarbons, lossis ethylene glycol acetate. Cov tshuaj uas siv tau, nrog tsawg kawg 50% dilution dej, yog diethylene glycol, ethylene glycol, thiab propylene glycol (antifreeze solutions).

7. Lub valve yuav raug ntsia nrog qhov kev taw qhia ntws zoo ib yam li tus xub ntawm lub cev valve. Kev teeb tsa tsis raug yuav ua rau lub cev hydronic tuag tes tuag taw.

8. Ob lub cocks kuaj txuas rau hauv lub thawv ntim khoom. Xyuas kom tseeb tias nws yuav tsum tau teeb tsa ua ntej pib ua haujlwm thiab yaug. Xyuas kom tseeb tias nws tsis puas tom qab kev teeb tsa.

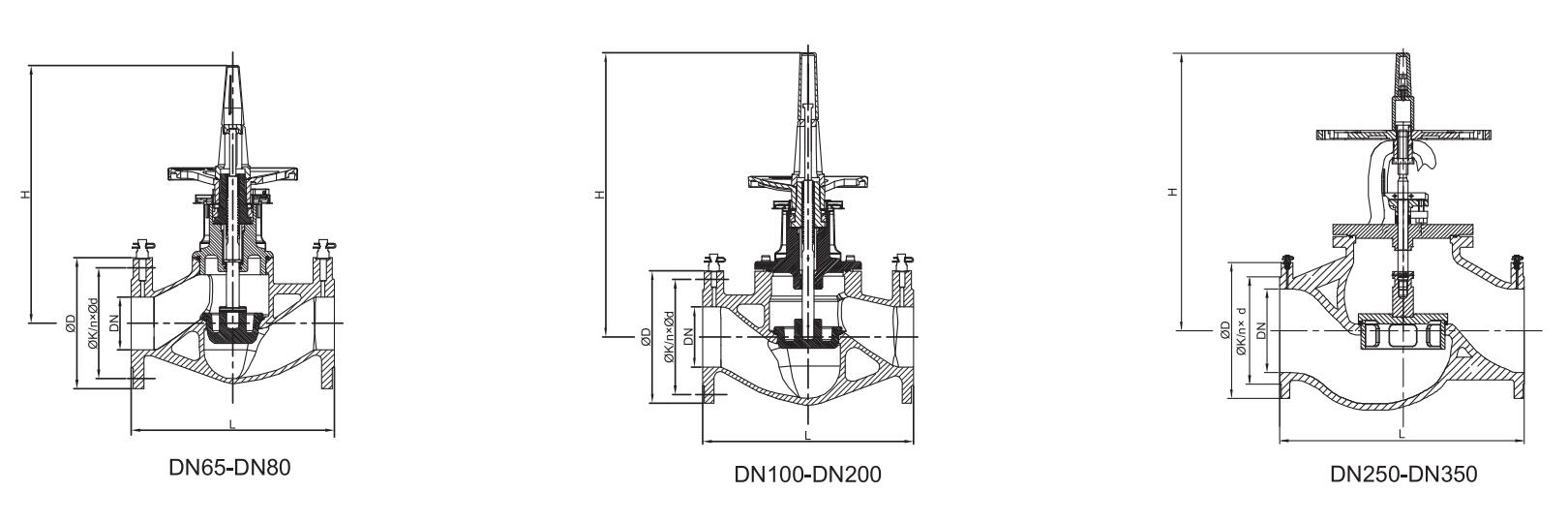

Qhov Loj:

| DN | L | H | D | K | tsis muaj dab tsi |

| 65 | 290 | 364 | 185 | 145 | 4 * 19 |

| 80 | 310 | 394 | 200 | 160 | 8 * 19 |

| 100 | 350 | 472 | 220 | 180 | 8 * 19 |

| 125 | 400 | 510 | 250 | 210 | 8 * 19 |

| 150 | 480 | 546 | 285 | 240 | 8 * 23 |

| 200 | 600 | 676 | 340 | 295 | 12 * 23 |

| 250 | 730 | 830 | 405 | 355 | 12 * 28 |

| 300 | 850 | 930 | 460 | 410 | 12 * 28 |

| 350 | 980 | 934 | 520 | 470 | 16 * 28 |