1. Kev tshuaj xyuas cov qauv

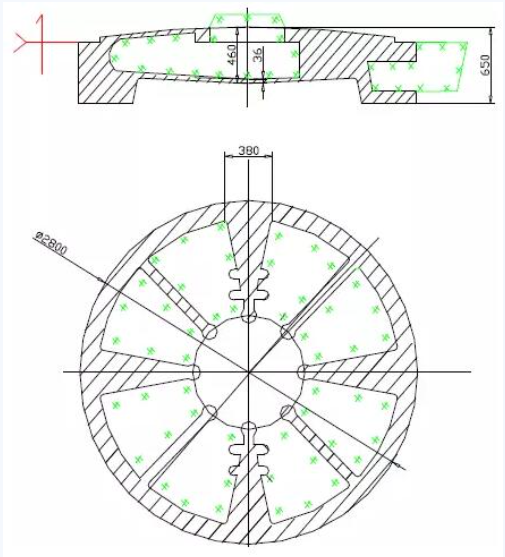

(1) Qhov nonpauj npaim valvemuaj cov qauv zoo li lub ncuav mog qab zib puag ncig, lub qhov sab hauv txuas nrog thiab txhawb nqa los ntawm 8 lub pob txha txhawb nqa, lub qhov Φ620 sab saum toj sib txuas lus nrog lub qhov sab hauv, thiab lwm qhov ntawmlub valveyog kaw lawm, lub hauv paus xuab zeb nyuaj kho thiab yooj yim rau deform. Ob qho tib si qhov tso pa tawm thiab kev ntxuav ntawm lub qhov sab hauv coj teeb meem loj heev, raws li pom hauv Daim Duab 1.

Lub phab ntsa tuab ntawm cov castings sib txawv heev, qhov siab tshaj plaws ntawm phab ntsa tuab ncav cuag 380 hli, thiab qhov tsawg kawg nkaus ntawm phab ntsa tuab tsuas yog 36 hli xwb. Thaum lub casting khov kho, qhov sib txawv ntawm qhov kub thiab txias loj heev, thiab qhov tsis sib xws ntawm qhov ntsws tuaj yeem ua rau cov qhov ntsws thiab qhov tsis zoo ntawm qhov ntsws, uas yuav ua rau dej ntws hauv qhov kev sim hydraulic.

2. Kev tsim cov txheej txheem:

(1) Qhov chaw sib cais tau qhia nyob rau hauv Daim Duab 1. Muab qhov kawg nrog cov qhov rau ntawm lub thawv sab saud, ua ib lub hauv paus xuab zeb tag nrho hauv qhov nruab nrab, thiab ntev lub taub hau tseem ceeb kom haum rau kev txhawb nqa ntawm lub hauv paus xuab zeb thiab kev txav mus los ntawm lub hauv paus xuab zeb thaum lub thawv tig mus. Ruaj khov, qhov ntev ntawm lub taub hau cantilever ntawm ob lub qhov muag tsis pom ntawm sab yog ntev dua qhov ntev ntawm lub qhov, yog li qhov chaw ntawm lub ntiajteb txawj nqus ntawm tag nrho lub hauv paus xuab zeb yog biased rau sab ntawm lub taub hau tseem ceeb kom ntseeg tau tias lub hauv paus xuab zeb yog kho thiab ruaj khov.

Ib lub kaw lus nchuav ib nrab raug saws txais, ∑F sab hauv: ∑F kab rov tav: ∑F ncaj = 1: 1.5: 1.3, lub sprue siv lub raj ceramic nrog lub cheeb sab hauv ntawm Φ120, thiab ob daim ntawm 200 × 100 × 40mm refractory cib raug muab tso rau hauv qab kom tiv thaiv cov hlau molten los ntawm ncaj qha Rau cov pwm xuab zeb cuam tshuam, lub lim dej ceramic ua npuas ncauj 150 × 150 × 40 tau teeb tsa rau hauv qab ntawm tus khiav, thiab 12 lub raj ceramic nrog lub cheeb sab hauv ntawm Φ30 yog siv rau tus khiav sab hauv los txuas sib npaug rau hauv qab ntawm qhov casting los ntawm lub tank sau dej ntawm hauv qab ntawm lub lim kom tsim cov phiaj xwm nchuav hauv qab, raws li pom hauv Daim Duab 2 Essence

(3) Muab 14 ∮20 qhov cua qhov rau hauv pwm sab saud, muab lub qhov cua xuab zeb Φ200 tso rau hauv nruab nrab ntawm lub taub hau tseem ceeb, muab cov hlau txias tso rau hauv cov khoom tuab thiab loj kom ntseeg tau tias qhov casting khov kho, thiab siv lub hauv paus ntsiab lus ntawm graphitization kom tshem tawm Lub tshuab pub mis siv los txhim kho cov txheej txheem tsim tawm. Qhov loj ntawm lub thawv xuab zeb yog 3600 × 3600 × 1000/600mm, thiab nws yog welded nrog 25mm tuab hlau phaj kom ntseeg tau tias muaj zog thiab rigidity txaus, raws li qhia hauv Daim Duab 3.

3. Kev tswj cov txheej txheem

(1) Qauv: Ua ntej qauv, siv tus qauv Φ50 × 50mm los sim lub zog compressive ntawm cov xuab zeb resin ≥ 3.5MPa, thiab nruj cov hlau txias thiab tus khiav kom ntseeg tau tias cov pwm xuab zeb muaj lub zog txaus los cuam tshuam cov graphite tsim tawm thaum cov hlau molten khov kho cov tshuaj lom neeg nthuav dav, thiab tiv thaiv cov hlau molten los ntawm kev cuam tshuam rau qhov khiav ntev ntev kom ua rau xuab zeb ntxuav.

Kev ua lub hauv paus: Lub hauv paus xuab zeb raug muab faib ua 8 qhov sib npaug los ntawm 8 lub pob txha txhawb nqa, uas txuas nrog los ntawm qhov nruab nrab. Tsis muaj lwm qhov kev txhawb nqa thiab qhov tso pa tawm tsuas yog lub taub hau hauv nruab nrab. Yog tias lub hauv paus xuab zeb tsis tuaj yeem kho thiab Pa tawm, lub hauv paus xuab zeb hloov chaw thiab qhov cua yuav tshwm sim tom qab nchuav. Vim tias thaj chaw tag nrho ntawm lub hauv paus xuab zeb loj, nws raug muab faib ua yim qhov. Nws yuav tsum muaj lub zog txaus thiab kev nruj kom ntseeg tau tias lub hauv paus xuab zeb yuav tsis raug puas tsuaj tom qab pwm tso tawm, thiab yuav tsis raug puas tsuaj tom qab nchuav. Kev hloov pauv tshwm sim, yog li kom ntseeg tau tias lub phab ntsa tuab sib npaug ntawm qhov casting. Vim li no, peb tau ua tshwj xeeb rau lub hauv paus pob txha tshwj xeeb, thiab khi nws rau ntawm lub hauv paus pob txha nrog txoj hlua cua kom rub cov pa tawm ntawm lub taub hau hauv paus kom ntseeg tau tias qhov compactness ntawm cov pwm xuab zeb thaum ua lub hauv paus. Raws li pom hauv Daim Duab 4.

(4) Kaw lub thawv: Xav tias nws nyuaj rau ntxuav cov xuab zeb hauv qhov hauv ntawm lub qhov ntawm lub npauj npaim valve, tag nrho cov xuab zeb core yog pleev xim nrog ob txheej xim, thawj txheej yog txhuam nrog cov xim zirconium cawv (Baume degree 45-55), thiab thawj txheej yog pleev xim thiab hlawv. Tom qab ziab, pleev xim rau txheej thib ob nrog cov xim magnesium cawv (Baume degree 35-45) kom tiv thaiv cov casting los ntawm lo rau xuab zeb thiab sintering, uas tsis tuaj yeem ntxuav. Lub taub hau core yog dai rau ntawm Φ200 steel yeeb nkab ntawm cov qauv tseem ceeb ntawm cov pob txha core nrog peb lub M25 ntsia hlau, kho thiab xauv nrog lub pwm xuab zeb sab saud nrog lub hau ntsia hlau thiab xyuas seb qhov tuab ntawm txhua qhov yog sib xws.

4. Cov txheej txheem yaj thiab nchuav

(1) Siv Benxi qis-P, S, Ti zoo Q14 / 16 # npua hlau, thiab ntxiv nws ntawm qhov piv ntawm 40% ~ 60%; cov ntsiab lus kab xws li P, S, Ti, Cr, Pb, thiab lwm yam raug tswj hwm nruj me ntsis hauv cov hlau seem, thiab tsis muaj xeb thiab roj raug tso cai, qhov sib piv ntxiv yog 25% ~ 40%; qhov them rov qab yuav tsum tau ntxuav los ntawm kev tua blasting ua ntej siv kom ntseeg tau tias qhov huv ntawm qhov them.

(2) Kev tswj hwm cov khoom tseem ceeb tom qab lub cub tawg: C: 3.5-3.65%, Si: 2.2% -2.45%, Mn: 0.25% -0.35%, P≤0.05%, S: ≤0.01%, Mg (residual): 0.035% ~ 0.05%, nyob rau hauv lub hauv paus ntawm kev ua kom spheroidization, qhov qis tshaj plaws ntawm Mg (residual) yuav tsum tau noj ntau li ntau tau.

(3) Kev kho mob Spheroidization inoculation: siv cov spheroidizers uas muaj magnesium tsawg thiab cov spheroidizers uas tsis tshua muaj neeg siv, thiab qhov sib piv ntxiv yog 1.0% ~ 1.2%. Txoj kev ntxuav ib txwm muaj kev kho mob spheroidization, 0.15% ntawm kev txhaj tshuaj ib zaug yog them rau ntawm lub nodulizer hauv qab ntawm pob, thiab kev txhaj tshuaj spheroidization tiav. Tom qab ntawd cov slag raug cog lus rau kev txhaj tshuaj thib ob ntawm 0.35%, thiab kev txhaj tshuaj ntws ntawm 0.15% yog ua tiav thaum lub sijhawm nchuav.

(5) Cov txheej txheem nchuav sai sai uas kub tsawg tau txais yuav, qhov kub nchuav yog 1320 ° C ~ 1340 ° C, thiab lub sijhawm nchuav yog 70 ~ 80 vib nas this. Cov hlau yaj tsis tuaj yeem cuam tshuam thaum lub sijhawm nchuav, thiab lub khob sprue yeej ib txwm puv kom tiv thaiv cov roj thiab cov khoom suav nrog los ntawm kev koom nrog hauv pwm los ntawm tus khiav. qhov.

5. Cov txiaj ntsig ntawm kev xeem casting

(1) Sim lub zog tensile ntawm lub thaiv xeem cam khwb cia: 485MPa, elongation: 15%, Brinell hardness HB187.

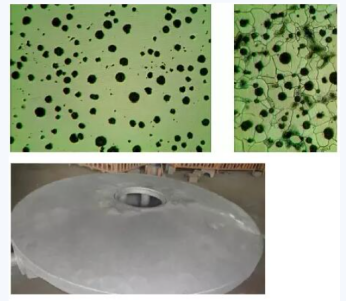

(2) Tus nqi spheroidization yog 95%, qhov loj ntawm graphite yog qib 6, thiab pearlite yog 35%. Cov qauv metallographic tau qhia hauv Daim Duab 5.

(3) Tsis muaj qhov tsis zoo uas sau tau hauv UT thiab MT qhov tsis zoo thib ob ntawm cov khoom tseem ceeb.

(4) Qhov tsos yog tiaj tus thiab du (saib Daim Duab 6), tsis muaj qhov tsis zoo xws li cov xuab zeb suav nrog, cov slag suav nrog, cov qhov txias kaw, thiab lwm yam, phab ntsa tuab yog sib xws, thiab qhov ntev ua tau raws li qhov yuav tsum tau ua ntawm cov duab kos.

(6) 20kg/cm2 hydraulic siab xeem tom qab ua tiav tsis qhia txog qhov xau.

6. Xaus Lus

Raws li cov yam ntxwv ntawm lub valve npauj npaim no, qhov teeb meem ntawm kev tsis ruaj khov thiab yooj yim deformation ntawm lub hauv paus xuab zeb loj hauv nruab nrab thiab kev ntxuav xuab zeb nyuaj yog daws tau los ntawm kev hais txog kev tsim cov txheej txheem, kev tsim khoom thiab kev kho ntawm lub hauv paus xuab zeb thiab kev siv cov txheej txheem zirconium. Kev teeb tsa ntawm cov qhov cua tsis pub muaj qhov ua tau ntawm cov qhov hauv cov castings. Los ntawm lub tshuab hluav taws xob tswj hwm thiab lub kaw lus khiav, ua npuas ncauj ceramic lim tshuaj ntsuam thiab cov thev naus laus zis ceramic ingate siv los xyuas kom meej tias cov hlau molten huv si. Tom qab ntau zaus kev kho mob, cov qauv metallographic ntawm castings thiab ntau yam Kev ua tau zoo tau mus txog cov qauv xav tau ntawm cov neeg siv khoom.

Los ntawmTianjin Tanggu Dej foob valve Co., Ltd. Npauj npaim valve, lub qhov rooj vag, Y-strainer, wafer ob lub phaj check valvetsim khoom.

Lub sijhawm tshaj tawm: Plaub Hlis-29-2023