Hoobkas Muag Ncaj Qha Npauj Npaim Valve Txheem Loj Ductile Cast Iron Wafer Kev Sib Txuas API Npauj Npaim Valve rau Dej Roj Roj

Tus yuam sij rau peb txoj kev vam meej yog "Khoom Muag Zoo, Tsim Nyog Tus Nqi thiab Kev Pabcuam Zoo" rau Kev Muag Khoom Kub Hoobkas Ductile Cast Iron Lug Hom WaferNpauj Npaim ValveAPI Npauj Npaim Valve rau Dej Roj Roj, Peb zoo siab tos txais koj los koom nrog peb hauv txoj kev no ntawm kev ua lag luam nplua nuj thiab muaj txiaj ntsig ua ke.

Tus yuam sij rau peb txoj kev vam meej yog "Khoom zoo, tus nqi tsim nyog thiab kev pabcuam zoo" rauTuam Tshoj Npauj Npaim Valve thiab Wafer Npauj Npaim Valve, Peb ib txwm tuav lub tuam txhab lub hauv paus ntsiab lus "ncaj ncees, kev tshaj lij, ua haujlwm tau zoo thiab kev tsim kho tshiab", thiab lub hom phiaj ntawm: cia txhua tus neeg tsav tsheb txaus siab rau lawv txoj kev tsav tsheb thaum hmo ntuj, cia peb cov neeg ua haujlwm tuaj yeem paub txog lawv tus nqi ntawm lub neej, thiab kom muaj zog dua thiab pabcuam ntau tus neeg. Peb txiav txim siab los ua tus neeg koom ua ke ntawm peb cov khoom lag luam thiab ib qho chaw muab kev pabcuam ntawm peb cov khoom lag luam.

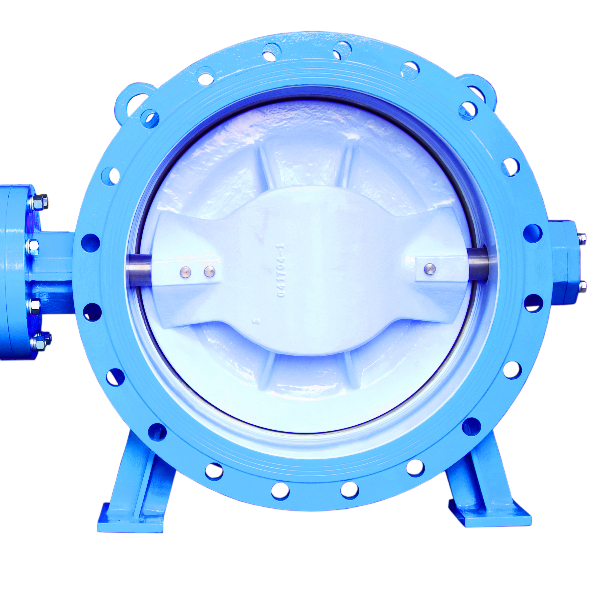

Kev piav qhia:

YD Series Wafer npauj npaim valve qhov kev sib txuas flange yog tus qauv thoob ntiaj teb, thiab cov khoom siv ntawm lub tes tuav yog txhuas; Nws tuaj yeem siv ua lub cuab yeej los txiav lossis tswj cov dej ntws hauv ntau yam kav dej nruab nrab. Los ntawm kev xaiv cov khoom sib txawv ntawm disc thiab lub rooj zaum foob, nrog rau kev sib txuas tsis muaj pin ntawm disc thiab qia, lub valve tuaj yeem siv rau cov xwm txheej phem dua, xws li desulphurization nqus tsev vacuum, dej hiav txwv desalinization.

Tsim los nrog kev ua haujlwm ntev, peb lub waferconcentric npauj npaim li qubyog tsim los ntawm cov ntaub ntawv zoo kom tiv taus cov xwm txheej kev lag luam hnyav tshaj plaws. Nws txoj kev tsim kho ruaj khov ua kom muaj kev ua haujlwm ntev thiab tsis tas yuav saib xyuas ntau, txuag koj lub sijhawm thiab nyiaj txiag rau lub sijhawm ntev.

Lub valve muaj lub qauv me me thiab tsis hnyav, ua rau nws yooj yim rau kev teeb tsa thiab ua haujlwm. Nws cov qauv wafer tso cai rau kev teeb tsa sai thiab yooj yim ntawm cov flanges, ua rau nws zoo tagnrho rau qhov chaw nqaim thiab cov ntawv thov uas tsis hnyav. Vim yog qhov yuav tsum tau muaj torque tsawg, cov neeg siv tuaj yeem kho qhov chaw ntawm lub valve kom yooj yim tswj kev ntws yam tsis muaj kev ntxhov siab rau cov khoom siv.

Qhov tseem ceeb tshaj plaws ntawm peb cov wafer npauj npaim li qub yog lawv cov peev xwm tswj kev ntws zoo heev. Nws cov qauv tsim disc tshwj xeeb tsim cov dej ntws laminar, txo qhov siab poob thiab ua kom muaj txiaj ntsig zoo tshaj plaws. Qhov no tsis yog tsuas yog ua kom koj lub cev ua haujlwm zoo xwb tab sis kuj txo kev siv hluav taws xob, ua rau koj txuag tau nyiaj ntau rau koj txoj haujlwm.

Kev nyab xeeb yog qhov tseem ceeb tshaj plaws hauv txhua qhov chaw ua lag luam thiab peb cov wafer npauj npaim valves tuaj yeem ua tau raws li koj xav tau. Nws muaj lub tshuab xauv kev nyab xeeb uas tiv thaiv kev ua haujlwm ntawm lub valve tsis raug lossis tsis raug cai, ua kom koj cov txheej txheem khiav tau zoo yam tsis muaj kev cuam tshuam. Tsis tas li ntawd, nws cov khoom kaw nruj txo qhov xau, ua rau lub kaw lus ntseeg tau ntau dua thiab txo qhov kev pheej hmoo ntawm kev tsis ua haujlwm lossis kev ua qias tuaj ntawm cov khoom.

Qhov ua tau ntau yam yog lwm yam zoo ntawm peb cov wafer resilient butterfly valves. Haum rau ntau yam kev siv xws li kev kho dej, HVAC systems, kev ua tshuaj lom neeg, roj thiab roj av, thiab ntau ntxiv, cov valves muab kev daws teeb meem kev tswj hwm zoo thiab siv tau zoo rau ntau yam lag luam.

Ncuav mog qab zibroj hmab zaum npauj npaim li qubmuab cov kev daws teeb meem tswj kev ntws txhim khu kev qha thiab pheej yig rau ntau yam kev siv. Nrog nws txoj kev tsim kho ruaj khov, kev teeb tsa yooj yim, kev tswj kev ntws zoo dua thiab cov yam ntxwv kev nyab xeeb ruaj khov, lub valve no yuav tsis muaj qhov tsis ntseeg dhau koj qhov kev cia siab thiab ua lub luag haujlwm tseem ceeb hauv kev ua kom zoo dua ntawm koj cov haujlwm. Paub txog kev ua tau zoo tsis sib xws ntawm peb cov wafer npauj npaim li qub thiab coj koj cov txheej txheem kev lag luam mus rau qhov siab tshiab.

Yam ntxwv:

1. Me me thiab sib dua thiab yooj yim kho. Nws tuaj yeem teeb tsa txhua qhov chaw xav tau.

2. Yooj yim, compact qauv, ceev 90 degree on-off ua haujlwm

3. Lub disc muaj ob txoj kev bearing, zoo meej foob, tsis muaj to nyob rau hauv lub siab xeem.

4. Cov kab ntws uas nyiam mus rau txoj kab ncaj. Kev ua haujlwm zoo heev.

5. Ntau hom ntaub ntawv, siv tau rau ntau yam xov xwm.

6. Muaj zog ntxuav thiab txhuam tsis kam, thiab tuaj yeem haum rau qhov xwm txheej ua haujlwm tsis zoo.

7. Lub phaj nruab nrab, lub zog me me ntawm kev qhib thiab kaw.

8. Lub neej ua haujlwm ntev. Sawv ntsug qhov kev sim ntawm kaum txhiab qhov qhib thiab kaw kev ua haujlwm.

9. Siv tau rau kev txiav thiab tswj cov xov xwm.

Daim ntawv thov ib txwm muaj:

1. Kev ua haujlwm dej thiab kev siv dej

2. Kev Tiv Thaiv Ib Puag Ncig

3. Cov Chaw Rau Pej Xeem

4. Fais fab thiab cov kev pabcuam pej xeem

5. Kev lag luam tsim kho

6. Roj av / Tshuaj lom neeg

7. Hlau. Kev lag luam hlau

8. Kev lag luam ua ntawv

9. Khoom noj / Dej haus thiab lwm yam

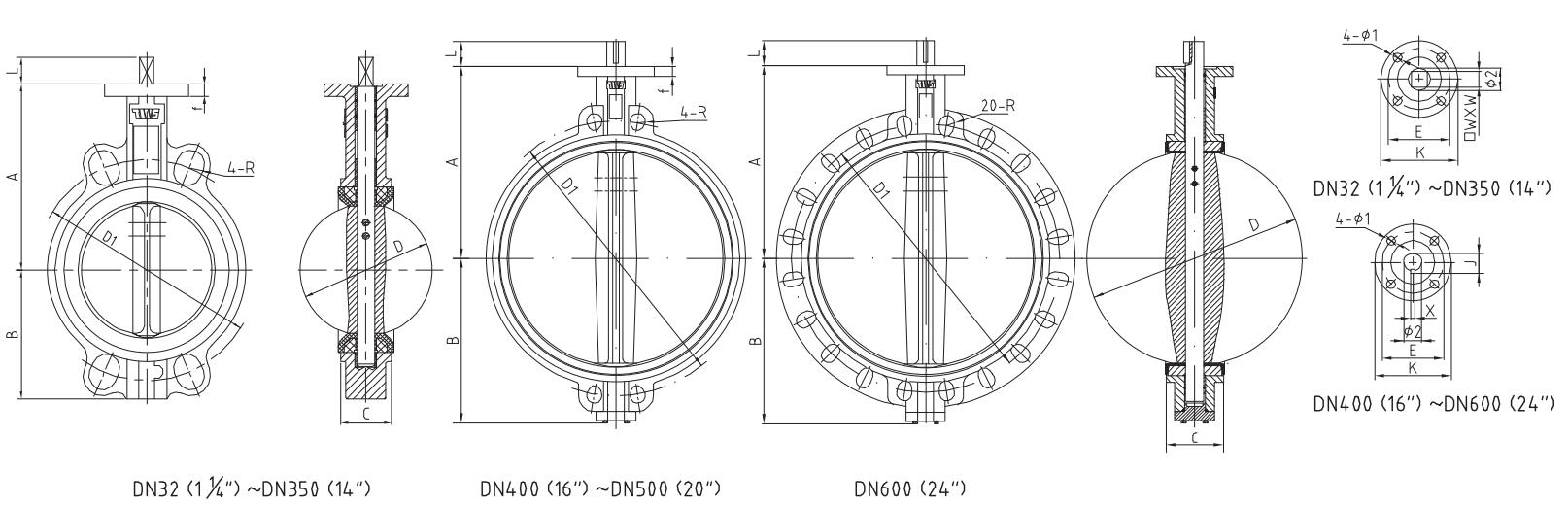

Qhov Loj:

| Loj | A | B | C | D | L | D1 | D2 | Φ1 | ΦK | E | R1 (PN10) | R2 (PN16) | Φ2 | f | j | x | □w*w | Qhov hnyav (kg) | |

| mm | nti | ||||||||||||||||||

| 32 | 11/4 | 125 | 73 | 33 | 36 | 28 | 100 | 100 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9 * 9 | 1.6 |

| 40 | 1.5 | 125 | 73 | 33 | 43 | 28 | 110 | 110 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9 * 9 | 1.8 |

| 50 | 2 | 125 | 73 | 43 | 53 | 28 | 125 | 125 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9 * 9 | 2.3 |

| 65 | 2.5 | 136 | 82 | 46 | 64 | 28 | 145 | 145 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9 * 9 | 3 |

| 80 | 3 | 142 | 91 | 46 | 79 | 28 | 160 | 160 | 7 | 65 | 50 | R9.5 | R9.5 | 12.6 | 12 | – | – | 9 * 9 | 3.7 |

| 100 | 4 | 163 | 107 | 52 | 104 | 28 | 180 | 180 | 10 | 90 | 70 | R9.5 | R9.5 | 15.8 | 12 | – | – | 11 * 11 | 5.2 |

| 125 | 5 | 176 | 127 | 56 | 123 | 28 | 210 | 210 | 10 | 90 | 70 | R9.5 | R9.5 | 18.9 | 12 | – | – | 14 * 14 | 6.8 |

| 150 | 6 | 197 | 143 | 56 | 155 | 28 | 240 | 240 | 10 | 90 | 70 | R11.5 | R11.5 | 18.9 | 12 | – | – | 14 * 14 | 8.2 |

| 200 | 8 | 230 | 170 | 60 | 202 | 38 | 295 | 295 | 12 | 125 | 102 | R11.5 | R11.5 | 22.1 | 15 | – | – | 17 * 17 | 14 |

| 250 | 10 | 260 | 204 | 68 | 250 | 38 | 350 | 355 | 12 | 125 | 102 | R11.5 | R14 | 28.5 | 15 | – | – | 22 * 22 | 23 |

| 300 | 12 | 292 | 240 | 78 | 302 | 38 | 400 | 410 | 12 | 125 | 102 | R11.5 | R14 | 31.6 | 20 | – | – | 22 * 22 | 32 |

| 350 | 14 | 336 | 267 | 78 | 333 | 45 | 460 | 470 | 14 | 150 | 125 | R11.5 | R14 | 31.6 | 20 | 34.6 | 8 | – | 43 |

| 400 | 16 | 368 | 325 | 102 | 390 | 51/60 | 515 | 525 | 18 | 175 | 140 | R14 | R15.5 | 33.2 | 22 | 36.2 | 10 | – | 57 |

| 450 | 18 | 400 | 356 | 114 | 441 | 51/60 | 565 | 585 | 18 | 175 | 140 | R14 | R14 | 38 | 22 | 41 | 10 | – | 78 |

| 500 | 20 | 438 | 395 | 127 | 492 | 57/75 | 620 | 650 | 18 | 175 | 140 | R14 | R14 | 41.1 | 22 | 44.1 | 10 | – | 105 |

| 600 | 24 | 562 | 475 | 154 | 593 | 70/75 | 725 | 770 | 22 | 210 | 165 | R15.5 | R15.5 | 50.6 | 22 | 54.6 | 16 | – | 192 |

Tus yuam sij rau peb txoj kev vam meej yog "Khoom Muag Zoo, Tsim Nyog Tus Nqi thiab Kev Pabcuam Zoo" rau Kev Muag Khoom Kub Hoobkas Ductile Cast Iron Lug Hom Wafer Npauj Npaim Valve API Npauj Npaim Valve rau Dej Roj Roj, Peb zoo siab txais tos koj los koom nrog peb hauv txoj kev no ntawm kev ua lag luam nplua nuj thiab muaj txiaj ntsig ua ke.

Hoobkas muag kubTuam Tshoj Npauj Npaim Valve thiab Wafer Npauj Npaim Valve, Peb ib txwm tuav lub tuam txhab lub hauv paus ntsiab lus "ncaj ncees, kev tshaj lij, ua haujlwm tau zoo thiab kev tsim kho tshiab", thiab lub hom phiaj ntawm: cia txhua tus neeg tsav tsheb txaus siab rau lawv txoj kev tsav tsheb thaum hmo ntuj, cia peb cov neeg ua haujlwm tuaj yeem paub txog lawv tus nqi ntawm lub neej, thiab kom muaj zog dua thiab pabcuam ntau tus neeg. Peb txiav txim siab los ua tus neeg koom ua ke ntawm peb cov khoom lag luam thiab ib qho chaw muab kev pabcuam ntawm peb cov khoom lag luam.